Proven Phases of Product Development

The product development process is an intricately woven journey, marked by a multitude of complex tasks. From the first idea to the final launch, each phase demands close attention to detail, strategic planning, and cross-disciplinary collaboration. Market research, technical feasibility, user-centered design, engineering, manufacturing, and quality testing all must be considered.

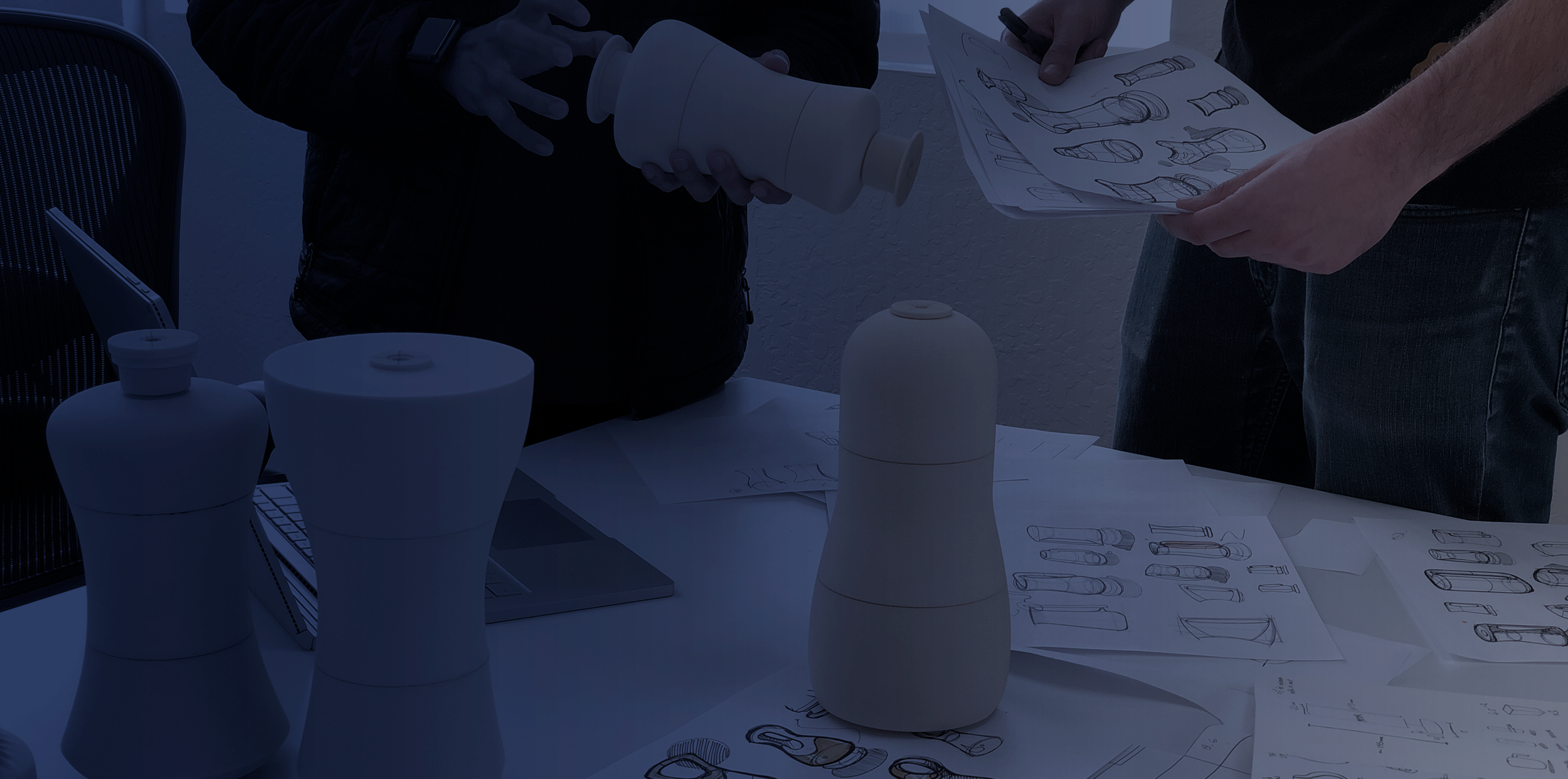

At Acorn we established a clear development path capable of navigating the intricate web of considerations when bringing your idea to life. While the tools used may change depending on the needs of a project, the goal of each phase listed below will remain reliably consistent. These are the proven phases of product development