The Heat Is On: Select The Right Thermal Strategy For Your Product

Electronics have never been hotter – literally. As devices become more powerful, compact, and interconnected, managing heat is a primary design challenge. Whether it’s a smartphone processor, a data center packed with AI servers, or the battery pack in an electric vehicle, proper thermal management enables higher performance and reliability.

The industry is at an inflection point. Conventional air cooling is reaching its limits in many applications, while advanced solutions like liquid cooling and two-phase systems are moving from niche to mainstream. The question is no longer whether cooling matters, but rather which approach offers the right balance of efficiency, cost, and scalability for a given application.

At Acorn Product Development, we’ve spent decades refining how to identify and integrate the right thermal strategy into products. From quick first-order calculations to advanced computational fluid dynamics (CFD), our product development process has helped leading companies solve their toughest heat challenges. This article demonstrates how applying thermal analysis at three critical stages of development leads to proven results across diverse industries.

Integrating Thermal Analysis into Early Development Stages

01: Building a Strong Thermal Foundation During Concept Development

Thermal management rarely has a single solution. For any given product, there are often multiple viable strategies — ranging from passive conduction and convection, to active cooling with fans or blowers, to more advanced methods like liquid cooling, immersion cooling or two-phase cooling systems. Each approach carries trade-offs in performance, cost, manufacturability, noise, size, and reliability.

During concept development thermal risks can be easily identified and addressed. At this stage, rapid order-of-magnitude calculations allow us to quickly evaluate power density, airflow potential, and surface temperatures. The advantage of concept-stage analysis is that we can model these solutions side by side, quantify their relative strengths and weaknesses, and eliminate high-risk options before they consume development resources. By the time a design moves into refinement, only the best-fit approach remains — one that balances thermal safety with business goals such as cost targets, product size, and time to market.

Case Study: Cooling Concepts

When one client asked us to design a thermal management system for its new product, the challenge was clear: maintain the external shape of the earlier design while doubling the power inside. Two processors and dual drives generated far more heat than the previous design could handle.

Our team brainstormed 25 possible cooling concepts and rapidly evaluated them with thermal analysis tools accurate to within ±20%. From there, we narrowed the field to the top two solutions and used detailed CFD simulations to validate performance. The final design introduced a parallel cooling scheme that separated airflow for the sensitive hard drive from the high-volume airflow needed for the massive heat sinks.

This process showed the value of early-stage analysis: before a single prototype was built, we had confidence in a design that delivered both performance and manufacturability.

Case Study: Managing Heat in a Handheld Device

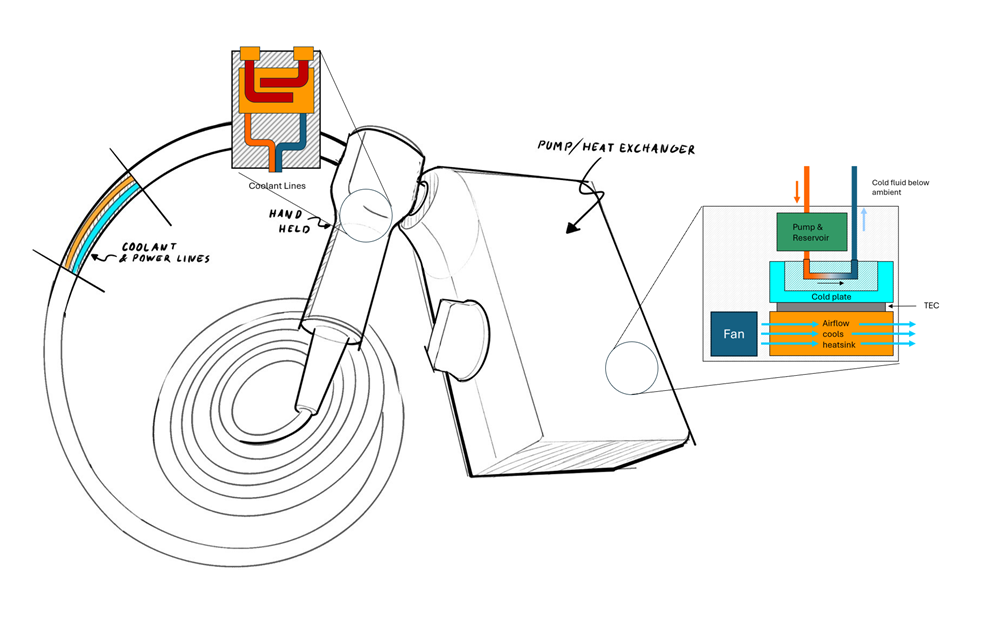

A client approached Acorn with the goal of packing five times more processing power into a handheld device — jumping from under 7W of passive cooling to as much as 30W. The device needed to remain small, lightweight, IP68-sealed, and safe to hold in 35°C environments. While the client’s early attempts explored immersion cooling it ultimately made the product too heavy and uncomfortably hot, highlighting the need for a more innovative approach.

During concept development, Acorn applied rapid order-of-magnitude thermal calculations to quickly rule out passive solutions. System-level fluid analysis revealed that only an off-board liquid cooling system could meet the thermal and ergonomic constraints. The early analysis also identified the need for a TEC to bring the incoming fluid lines at a below ambient temperature. Using the device’s existing power cables as a pathway to also carry coolant lines, our team modeled flow rates, tubing restrictions, and estimated surface temperatures. This early insight established the foundation for a feasible cooling strategy that balanced power, weight, and usability — ensuring the project moved forward with confidence.

02: Testing Trade-Offs and Narrowing Options During Concept Refinement

Once promising concepts are identified, the next step is refining them through targeted analysis. Spreadsheet models, resistance diagrams, and simplified CFD simulations provide a clearer view of airflow distribution, component temperatures, and pressure drops. At this stage, design trade-offs around layout, size, and cost can be evaluated quickly.

Case Study: Analyzing Airflow in a Chassis

A client approached us with concerns about a new chassis design after experiencing failures in an earlier model. Their system included two airflow paths: one with strong fans pulling air through a packed channel, and another with weaker fans in a less constrained path. Small leaks between the channels created pressure differences that caused airflow to reverse through the weaker fan — an issue their earlier analysis had missed.

By modeling both airflow paths together, we identified the critical leak points and evaluated multiple solutions. Some were impractical due to cost or serviceability, so we simulated small leaks to understand the trade-offs. We also tested scenarios where the stronger fans ran at reduced power, which equalized pressure and allowed weaker fans to perform effectively. Ultimately, the solution was a new layout that allowed fans to work cooperatively instead of against each other.

This outcome wouldn’t have been possible with oversimplified models. Our refined analysis struck the right balance: detailed enough to catch system-level risks, but efficient enough to guide design trade-offs early.

03: Precision Analysis for Final Validation During Detail Design

In the detailed design phase, the primary architecture is locked, and thermal analysis becomes highly granular. CFD simulations are run on full 3D CAD models, producing detailed results such as chip-level temperature variations, airflow velocities, and pressure plots. These insights allow for final adjustments before committing to costly prototypes.

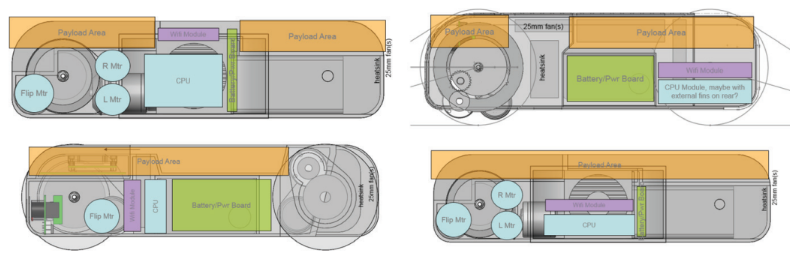

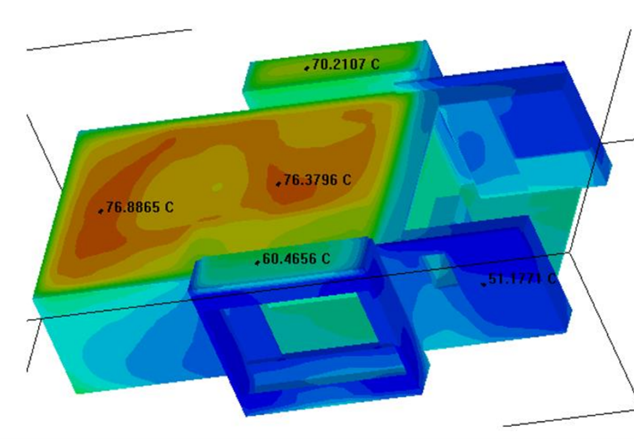

Case Study: Optimizing Robotex’s Portable Robotic Rover

Robotex, a startup creating rugged robotic rovers for first responders, needed to redesign its system to reduce weight, extend battery life, and improve thermal performance. Their IP65-rated enclosure had to dissipate 250W of power while also withstanding desert sun exposure — equivalent to 600 W/m² of additional heat load.

We began with first-order calculations to evaluate layouts and component placements. From there, simplified CFD models were built to analyze critical sub-assemblies to more accurately input their performance into the overall system model. A matrix of results allowed Robotex to weigh trade-offs in weight, heat sink size, and fan power while ensuring safe plastic touch temperatures under 60°C.

In the final design phase, we developed a detailed system-level CFD model to fine-tune component temperatures. The prototype that followed validated our models within 15% accuracy. By layering analysis throughout the design cycle, Robotex achieved an optimized rover design on an accelerated schedule — ready for real-world deployment.

Why Iterative Thermal Analysis Matters

Thermal analysis isn’t just about preventing overheating, it’s about identifying the right cooling method for your product in the long run. Iterative analysis makes it possible to:

• Integrate cooling into the design from the start

• Balance cost, energy use, and long-term reliability

• Prepare for higher power densities in future generations

• Support sustainability with energy-efficient and recyclable solutions

No matter the industry, iterative thermal analysis guides teams toward the most effective solution—whether that’s a vapor chamber in a phone, a liquid cold plate in an EV, or immersion cooling in a data center.

Conclusion

Thermal management is both a technical necessity and a strategic differentiator. From low-cost passive heat sinks to advanced immersion systems, each method carries distinct advantages and limitations. Identifying the right thermal strategy can ensure innovative products can withstand the heat of the future

At Acorn Product Development, we’ve helped clients such as Apple, Google, Hp, Cisco and many more achieve exactly that. Whether it’s rethinking airflow in a complex chassis, keeping high-power chips cool in handheld devices, or validating rugged systems for extreme environments, our proven methodology delivers cool solutions to hot problems.

The heat is on — but with the right approach, you can stay ahead of it.