Why Engineering Quality Analysis Matters: Bugatti Edition

Will knockoff Bugatti wheels reach catastrophic failure at 200 mph in the Arizona desert? That’s the bold experiment VinWiki’s Ed Bolian set out to answer with his Bugatti Veyron Grand Sport. Hypercar wheels aren’t just styling accessories — they are critical load-bearing components engineered to survive extreme forces. The stakes? At 200 mph+, the structural loads on a wheel are immense, with centrifugal forces and vertical loads far beyond everyday driving conditions.

Why Engineering Quality Analysis Matters

Supercars, like the Bugatti Veyron, are engineered with extreme precision. OEM wheels undergo extensive structural, fatigue, and dynamic testing to ensure reliability at top speed, a level of precision that’s reflected in their staggering price. At speed, every gram of mass, and every interface of material and geometry, is part of a carefully balanced system. Even minor deviations in strength or stiffness can lead to catastrophic failures under load.

That’s why any attempt to substitute components demands far more than visual inspection.

From Idea to Reality: Testing Before the Run

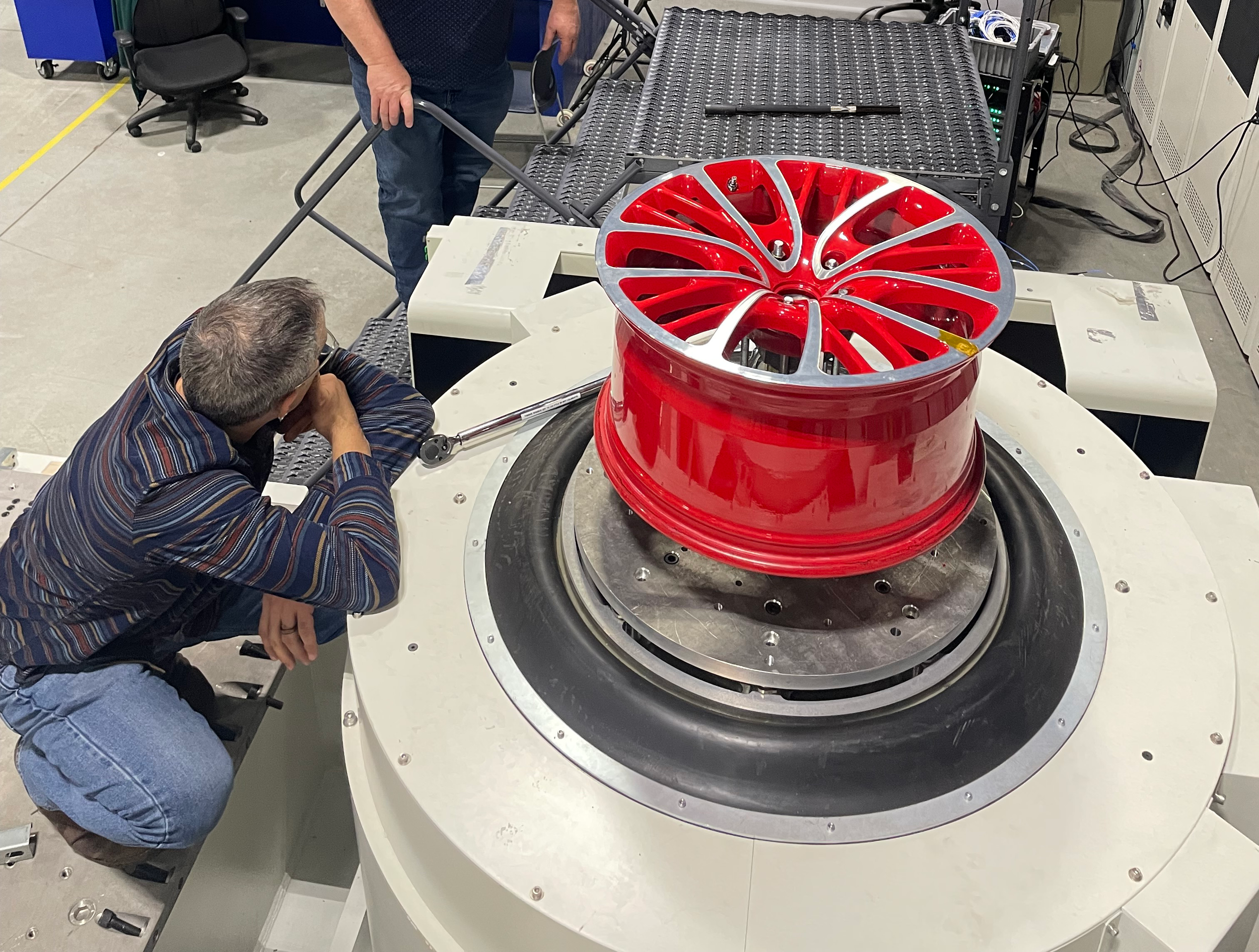

Rather than simply bolting on inexpensive replica wheels and hoping for the best, Ed Bolian took the responsible step of conducting a rigorous engineering analysis first. A pair of forged-aluminum replica wheels, priced at a fraction of the OEM set, was sent to Unified Global Packaging in Massachusetts for rigorous evaluation.

There, the wheels underwent:

Vibration table testing to simulate real-world forces seen at highway and track speeds, checking for fatigue and resonance effects.

20-ton press loading to compare their structural response against the original Bugatti wheels.

These pre-tests aren’t optional — they’re fundamental engineering safeguards to ensure structural integrity before risking human life and multimillion-dollar equipment.

The Role of Acorn Product Development & Apex Ridge

Acorn Product Development and Apex Ridge entered the project as engineering partners, not observers, bringing deep expertise in structural analysis, materials evaluation, and high-performance product validation. That rigor fundamentally altered the character of the work, elevating it from a stunt to a scientifically grounded experiment.

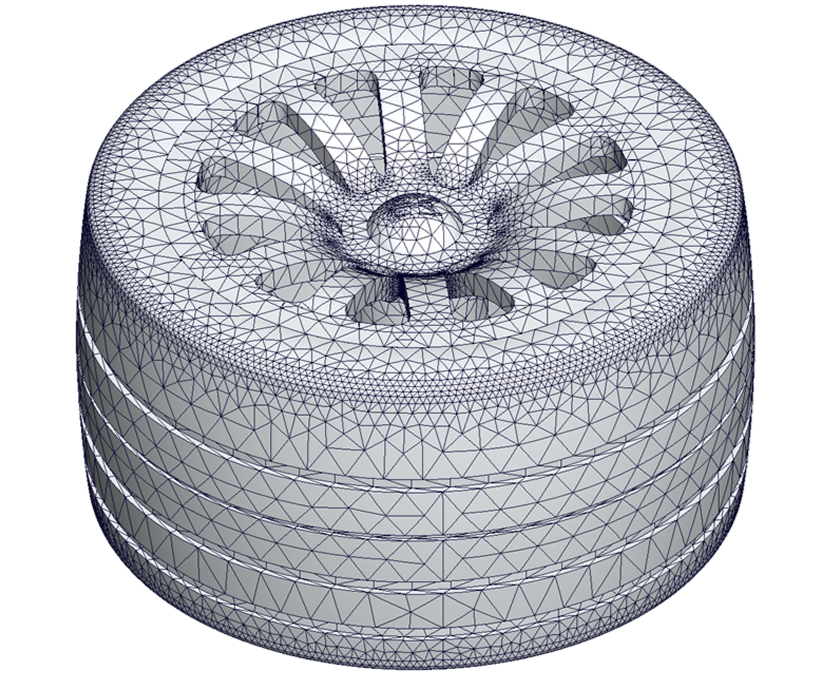

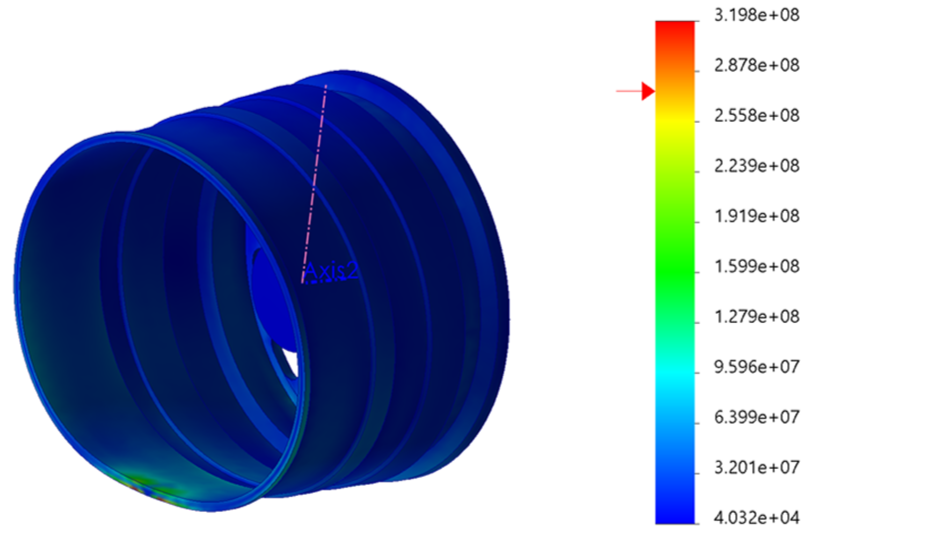

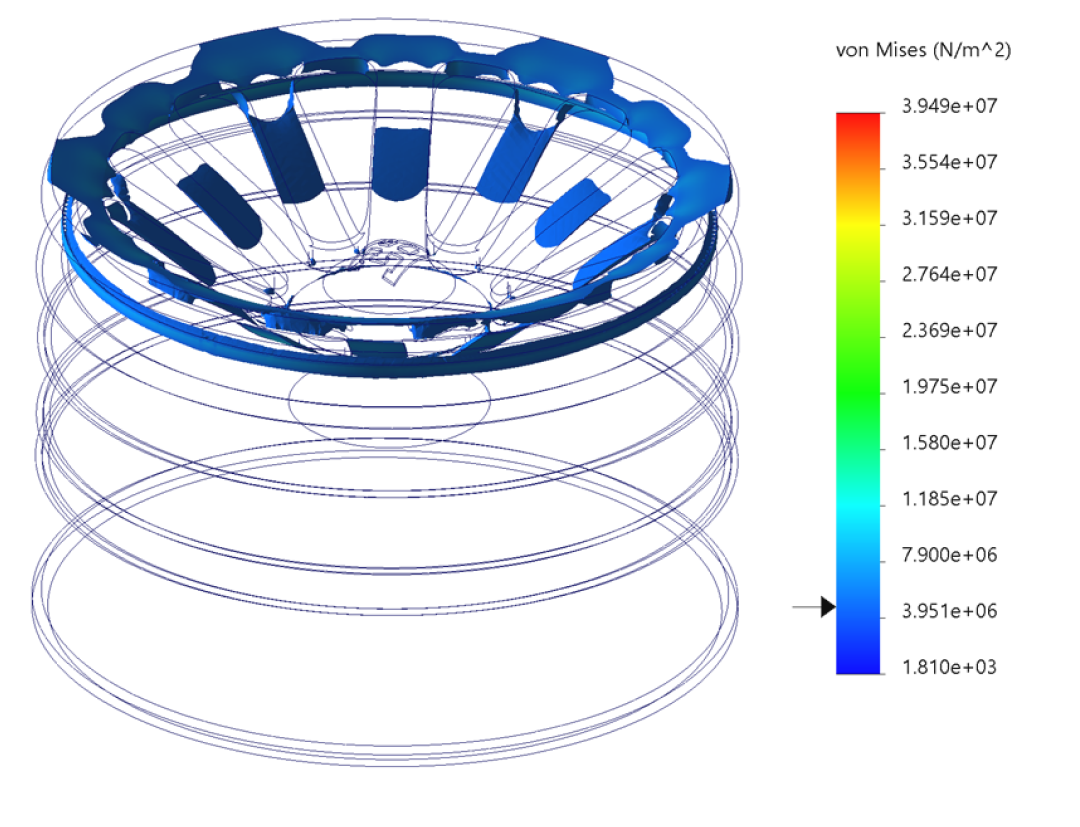

Specifically, Acorn applied:

Finite element analysis (FEA) and load simulations to predict stress distributions under rotational and impact loads.

Failure mode analyses to assess what could go wrong and under what conditions.

Design review and test planning to ensure that lab tests at Unified would yield meaningful, comparable results.

These analyses helped validate confidence in the replica wheels before the Bugatti ever hit top speed. This is the type of proactive engineering rigor that distinguishes safe innovation from dangerous experiments.

High-Speed Reality: What Happened on the Run

With lab validation complete and the wheels now backed by data, they were ready for the runway. Despite rain and less-than-ideal conditions, Ed Bolian engaged the Veyron’s Top Speed Mode and reached an extraordinary 200 mph, without wheel failure.

It’s a testament not only to the manufacturing quality of the replica wheels but more importantly to the engineering process behind validating them. Engineering quality analysis ensured that performance wasn’t left to chance.

Why This Matters for Product Innovators

This case isn’t just about cars and wheels — it’s about how engineering quality analysis de-risks innovation. Whether you’re developing a consumer product, an automotive component, or a medical device, understanding how components behave under real-world loads is essential. Engineers don’t guess — they analyze, simulate, test, and validate.

That’s the differentiator Acorn brings to clients:

A structured approach to identifying real risks before they become failures.

The ability to apply rigorous engineering tools to ambitious ideas.

A mindset that balances innovation with safety and performance.

When the world watches a Veyron hit 200 mph on $3,700 wheels, it shouldn’t just marvel at the spectacle — it should recognize the engineering foundation that made it possible.