Accelerating Science With Good Design

In the life science industry, every second and every sample matters. The pace of innovation is relentless, and researchers are expected to deliver faster, more accurate results using tools that weren’t necessarily designed with them—or their workflows—in mind. While breakthroughs in biology and chemistry capture headlines, it’s often the overlooked collaboration between design and engineering that determines whether scientific discovery can truly accelerate.

At Acorn Product Development, we’ve learned that great design doesn’t just make equipment look better—it makes science work better.

Design as an Accelerator

When we talk about "design" in the context of life science equipment, we’re not just referring to aesthetics. We mean user-centered design, ergonomic interfaces, intuitive workflows, and systems that reduce cognitive and physical strain. In high-stakes lab environments, the tools must support, not slow down, the science.

Too often, researchers are forced to adapt to tools that weren’t built with their real-world needs in mind—leading to workarounds, wasted time, and even errors.

Many lab products prioritize technical specs over practical usability, leading to inefficiencies and frustration. This misalignment between design and use isn’t just inconvenient—it’s a barrier to progress.

At Acorn Product Development, we’ve learned that great design doesn’t just make equipment look better—it makes science work better.

What to Consider When Designing for the Lab

Here are key factors to consider during life science equipment development that truly accelerate discovery:

1. Workflow Integration

A successful piece of lab equipment should integrate seamlessly into existing workflows. That means understanding the context in which it will be used: the order of operations, the handoffs between steps, and the physical environment. Good design starts with shadowing scientists, mapping tasks, and identifying friction points.

Example: In one Acorn project, simply reorienting a component’s loading position reduced a multi-step process by 30%, eliminating the need for awkward maneuvers and freeing researchers to focus on analysis, not equipment gymnastics.

2. Ergonomics and Human Factors

Scientists often perform repetitive, high-precision tasks in tight, stressful environments. Poor ergonomics can lead to fatigue, injury, and costly mistakes. Every screen, button, latch, and access point must be placed intuitively—but also be engineered to perform consistently, even with gloved hands or under frequent use.

At Acorn, our industrial designers work closely with mechanical engineers to prototype mockups, test reach and motion, and refine usability. We look at wrist angles, load forces, and visibility—then ensure the final mechanism works as well as it feels.

3. Footprint and Space Optimization

Bench space is gold in any lab. Great design should maximize vertical and horizontal space through clever layouts and modularity, while engineering should ensure that everything fits, functions, and stays cool under pressure.

Engineers may miniaturize PCBs, develop fold-out components, or arrange internal structures to optimize airflow and serviceability. Designers then must wrap those complex internals in an intuitive, compact enclosure that fits seamlessly into the lab.

On one project, engineers stacked internal boards and redirected airflow to shrink the footprint, while designers found a way to preserve full access to the interface and make cable routing easier.

4. Serviceability and Scalability

Labs move fast and stopping for repairs can be costly. Equipment in research and clinical labs needs to be easy to maintain and repair. Designers and engineers should consider how users—or service technicians—will access internal components for calibration, part replacement, or software updates.

This includes designing modular assemblies, quick-access panels, and diagnostic indicators that reduce downtime. Fasteners, PCBs, and wiring should be arranged for accessibility without compromising safety.

Equipment that can’t adapt becomes obsolete quickly. Modular design allows researchers to expand capabilities without reinvesting in entirely new systems. Swappable cartridges, adjustable fixtures, or software-driven upgrades make devices more versatile and futureproof.

5. Cleanability and Sterility

Designing for cleanability is critical in environments where contamination can compromise experiments—or worse, patient safety. Materials, surface finishes, and parting lines all matter. Equipment must withstand harsh cleaning agents, repeated sterilization, and still look and function like new.

By combining engineering and design expertise it allows the ideal CMF (Color, Material, Finish) to be selected for each project. Understanding the tradeoffs allows a design team to prioritize seamless enclosures, minimal crevices, and durability requirements to ensure the longevity of any product.

6. Temperature, Humidity, and Airflow Control

Labs often operate under tightly regulated environmental conditions. Equipment must be engineered to function reliably in spaces with constant airflow (e.g., laminar flow hoods), varying humidity levels, or temperature-sensitive workflows. Materials need to be chosen not just for durability but for stability under these conditions.

For example, plastics that warp under moderate heat or metals prone to corrosion can introduce failure risks. Thermal management—such as passive heat dissipation or active cooling—should also be designed with lab airflow patterns in mind to avoid disrupting sensitive experiments.

7. Intuitive User Interface Design

Whether digital or physical, interfaces must be self-evident. Users should know the status of the device at a glance and be able to operate it without constant reference to a manual. Clear visual cues, haptic feedback, and error-proofing features (like keyed connectors or one-way assembly) enhance usability and reduce mistakes.

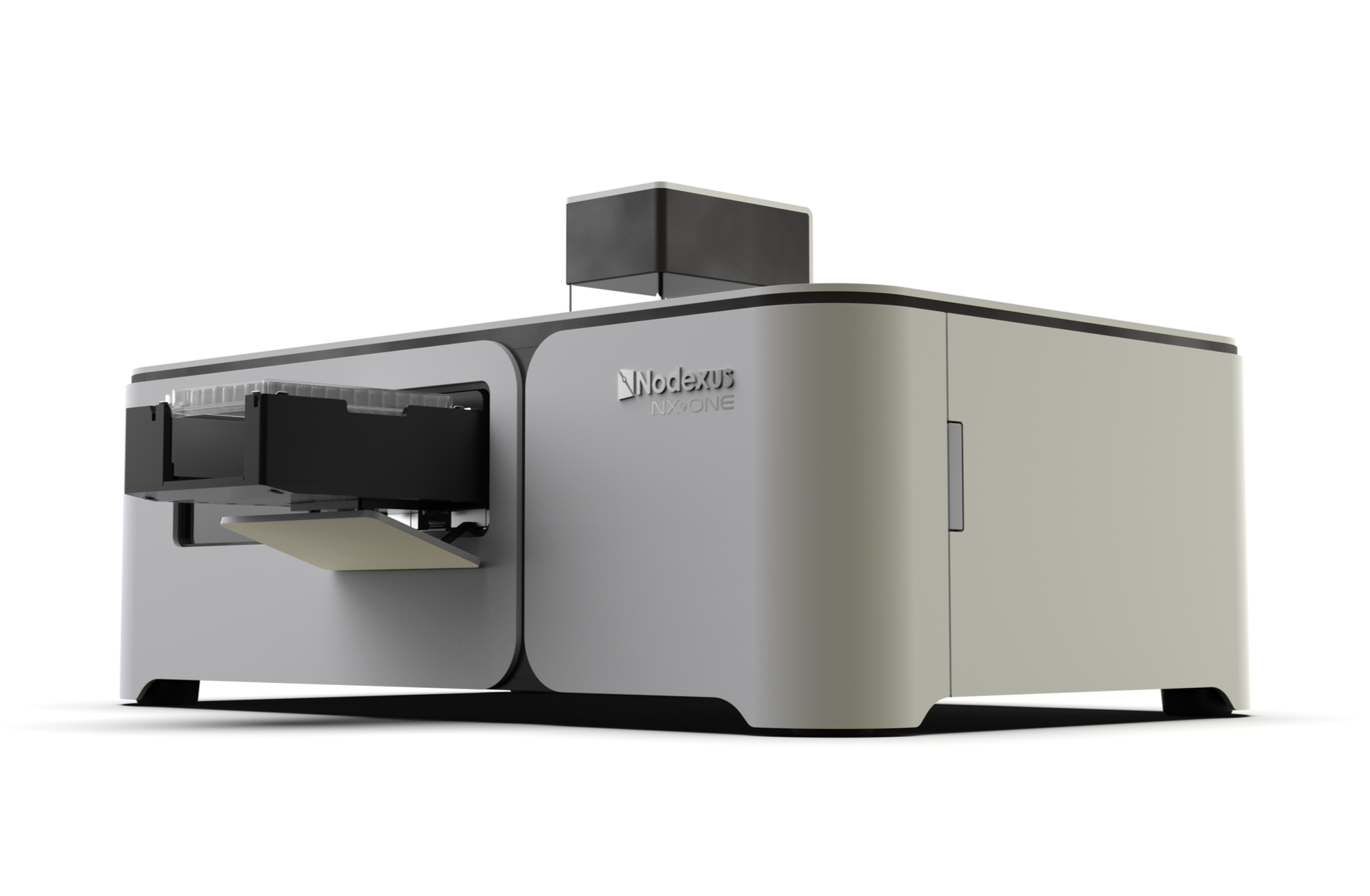

8. Visual Brand Language and Trust

In medical and lab environments, aesthetics aren't just about style—they communicate trust. A well-designed device signals professionalism, cleanliness, and technological maturity. Thoughtful use of color and form language can differentiate a product in the marketplace while reinforcing its scientific legitimacy.

The Value of Co-Development

The best results come when designers, mechanical engineers, and scientists collaborate from the start. Too often, design is treated as a sequential step or skipped altogether. In our experience, embedding multiple disciplines early and nurturing continued collaboration leads to more innovative, more manufacturable, and more user-friendly solutions.

Good design isn't a luxury—it's a competitive advantage. In life science development, it's the difference between frustration and flow, between wasted effort and accelerated discovery.

In Conclusion

When developing a Life Science, IVD, or complex medical device, success depends on a deep understanding of the people who use the tools and the science they support. At Acorn, we believe that when design and engineering are aligned—and rooted in real-world lab conditions—they become a powerful force for innovation.

In the race to push life sciences forward, it’s not just what your product does. It’s how seamlessly it fits into the lab, how reliably it performs, and how naturally it supports the scientist behind the breakthrough.

Let’s design and engineer the future of science together!