Acorn Product Development

Acorn Product Development is a leading provider of product development consulting, offering comprehensive design and engineering services. With our specialized expertise, we guide businesses to bring their innovative product ideas to life. From initial concept to final implementation, our team of professionals lead you through every step of the product development process. We provide the strategic and technical insights needed to drive the success of your product initiatives across multiple industries.

-

When developing a regulated IVD and RUO device it’s important to partner with an experienced team. Acorn knows the importance of meeting cost targets and clearly defining the assay early in the development process.

-

When developing a product for the medical industry there are a range of regulatory requirements that need to be met. At Acorn we have experience providing 13485 engineering design and documentation focused on gaining the required approvals without forgetting about the users that the product benefits.

-

Acorn specializes in making things move. We develop novel mechanical and automated solutions that push the boundaries of robotics and have explored a diverse range of exciting products over the years, from walking quadrupeds and talking animatrons to amusement park rides and large-scale automated industrial machinery.

-

Combining design, engineering, and manufacturing expertise, we discover user insights, navigate through development complexity, and bring your product to the market before your competitors do.

-

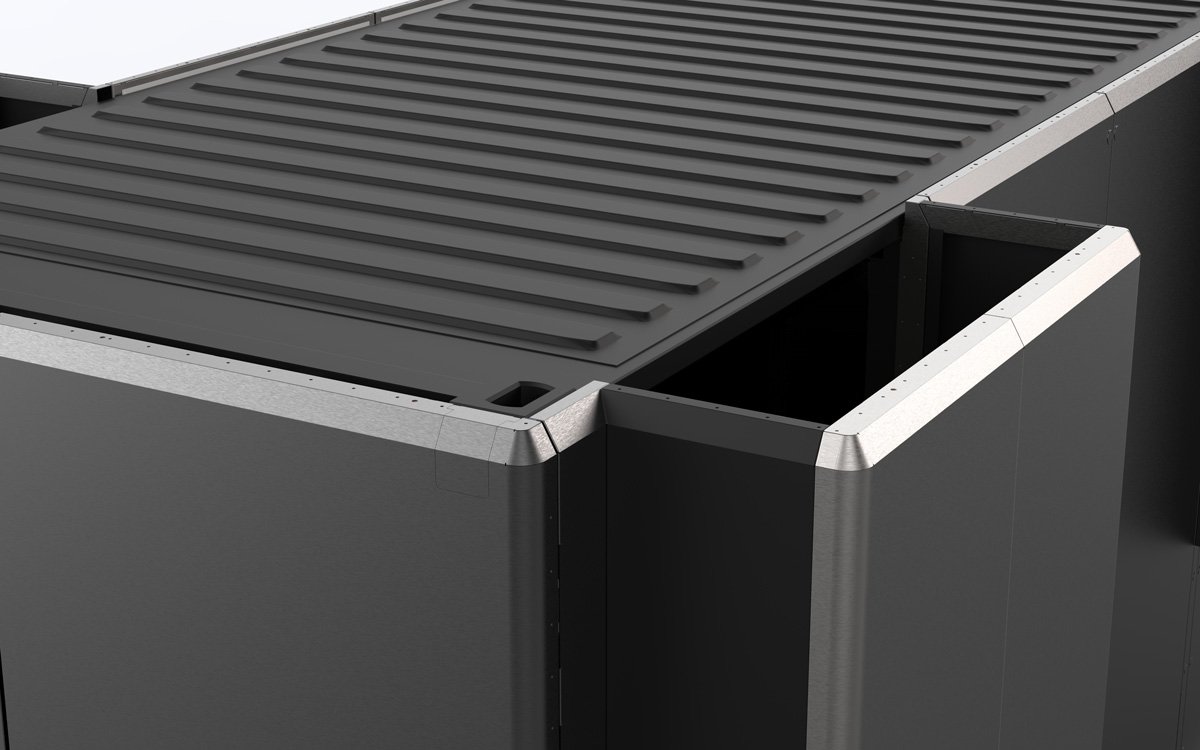

Acorn Product Development has been designing, engineering, testing, and providing production support for industrial products globally since its inception 30 years ago. Our development process ensures precision, reliability, safety, and manufacturability.

Product Engineering

Engineers are called upon to design and deliver products. They ideate, build, and test their concepts within industry standards and program goals. Our talented team has left its mark in the medical, robotics, life science, and consumer industries.

User-Centered Design

Our multidisciplinary design capabilities include user experience design, industrial design, user interface design, and brand identity. These various disciplines collaboratively explore unspoken needs, identify what triggers emotional appeal, and develop user experiences that captivate your customers.

Manufacturing Support

Acorn works with clients to identify the best CM for each product’s unique requirements. We transfer our in-depth knowledge of a product’s design – from identifying critical to function dimensions, and tolerances analysis, to the impact on the product if changes are requested by a CM to improve manufacturability/yield.

Explore.

At Acorn, listening deeply and engaging inquisitively are key components in how we approach our product development process. We first take the time to get to know our clients and their product development goals. We then design bespoke programs to match the uniqueness of our clients and their challenges. The key is understanding and empathizing with our client’s target market so we can appropriately explore products and services crucial to our client’s success.

Execute.

This is reflected in our two main competencies, user-centered design, and product engineering. UCD helps us to realize the intent of the product, while engineering makes that intent a reality. Our approach to engineering starts at a creative place and drives to a technical solution while design begins at a technical place and drives to a creative solution. Striking the appropriate balance between these integrated disciplines allows us to execute superior product development programs and outcomes.

Empower.

At the core of Acorn Product Development, the goal is to empower our clients in everything we do, which separates the vendors from the partners. As a partner we advocate for you in the community, help make needed connections, integrate you into our network, and educate your team on best development practices. More importantly, the partnership benefits your continuous growth long after the development program has been completed.

We Succeed by Caring About Our Clients

30 Years of Product Development Expertise

For 30 years Acorn has provided clients with the tools they need to succeed. From concept development to production support, our integrated engineering and design team has the skills to produce market success. No matter where you are in your product development journey, we can help you overcome hurdles to get your product into the hands of the consumer.