Cisco: Nexus 9500 Series

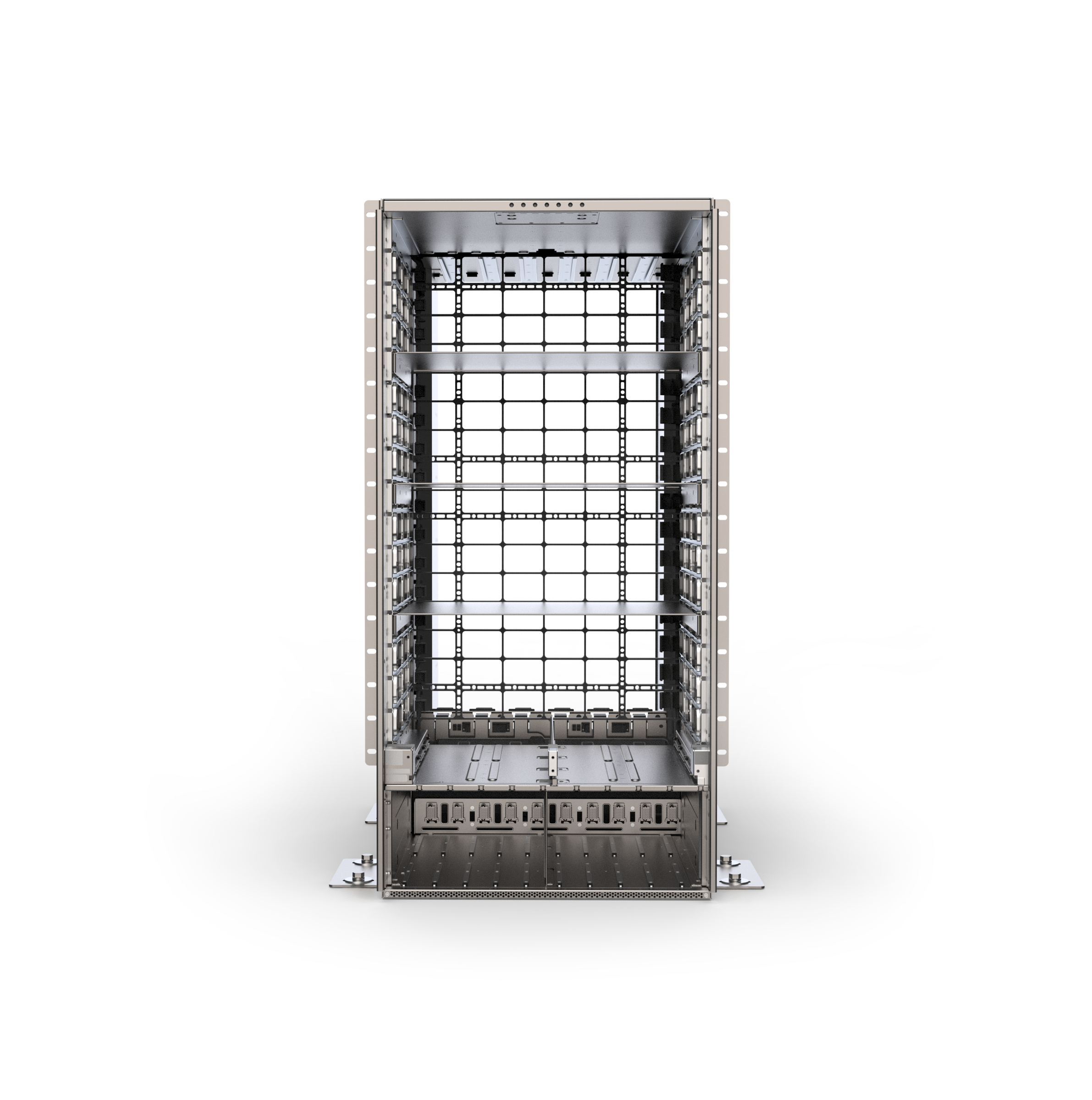

When Cisco set out to launch the Nexus 9500 series, they needed a breakthrough chassis architecture—one that could handle increasing bandwidth demands, maximize airflow, and remain cost-efficient at scale.

The challenge: design a midplane-less chassis using the Molex Impact Orthogonal Direct (OD) Connector, enabling direct module-to-module communication without the cost, bulk and airflow restrictions of a traditional midplane.

The payoff was compelling—greater performance and cooling capacity. But it demanded something that had never been attempted at this scale: achieving precise structural alignment across dozens of high-speed connections in a floating matrix that would be manufactured globally and at volume.

That’s where Acorn Product Development came in.

Capabilites

Project Management

Architectural Layout

Concept Development

Mechanical Design & Engineering

Our Approach

-

Identifying reliable connector engagement and mating for signal integrity was the highest system level risk, Acorn began with rough CAD modeling and tolerance loop analysis to explore every possible chassis architecture. Each design was evaluated not only for performance but also manufacturability at scale.

This upfront rigor gave Cisco confidence in the path forward and ensured the design wasn’t just innovative, but also feasible.

-

Ease of assembly was critical. Instead of slowing down manufacturing with external fixtures, Acorn designed self-aligning features — slots, tabs, and half-shears — directly into the chassis structure.

The first assembled prototype hit its alignment targets with zero external fixturing required.

-

Molex offered off-the-shelf alignment pins and shrouds, but they increased cost and restricted airflow. Acorn instead designed a new guide pin system independent of the connectors, reducing required pins to just three per module.

This simplified assembly, cut material costs, and preserved airflow all while ensuring repeatable alignment.

-

To make the architecture viable, Acorn created a new center structure; a die-cast aluminum backbone that served as both the structural anchor and the primary gathering feature for all modules.

Initially explored in sheet metal, the design transitioned to die-casting with secondary machining. This approach provided structural rigidity, achievable tolerances, and cost efficiency in one package. Beyond precision, the structure also had to withstand hundreds of pounds of insertion force as modules were connected simultaneously. Balancing that level of strength and stiffness with a design that operators could still assemble and service without excessive effort required careful analysis of load paths, material thickness, and ergonomic considerations. The result was a solution that was both robust under stress and intuitive in use.

-

Large die-cast parts introduced risks: warpage, distortion during machining, and tolerance drift. To solve this, Acorn worked hand-in-hand with global suppliers to:

Define achievable tolerances based on real-world production data.

Analyze how warpage would impact critical features, then refine machining sequences to minimize errors.

Define focus datums and precision machining only where alignment mattered most, while holding surrounding areas to NADCA-standard tolerances.

By engineering the part to be machined from a single direction, setup time and cost were drastically reduced. The result was a 90% cost reduction compared to fully machined prototypes — without compromising reliability.

Conclusion

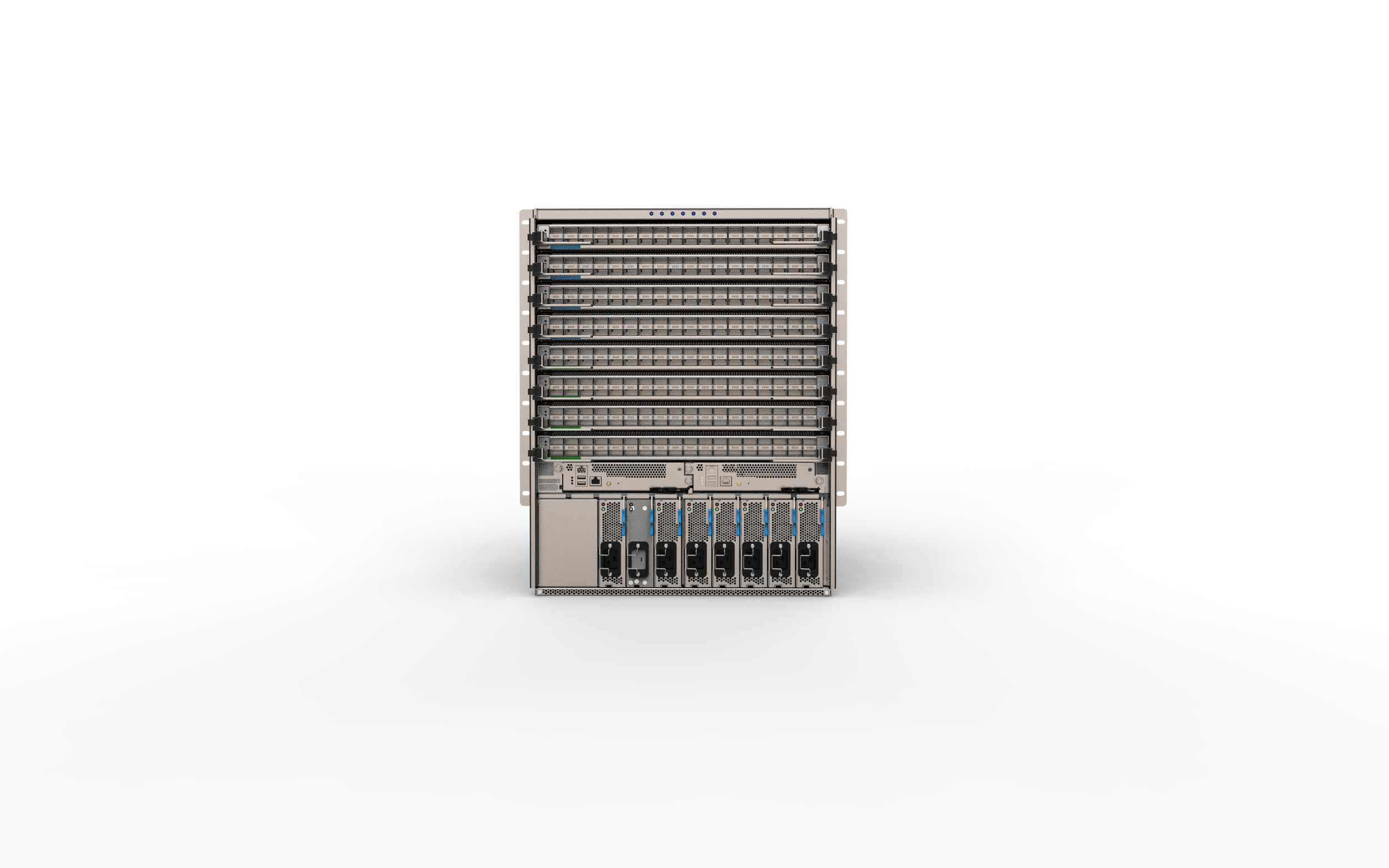

Through a combination of engineering rigor, design innovation, and supplier collaboration, Acorn delivered a chassis architecture that met Cisco’s performance and cost targets while breaking new ground in switch design.

The Cisco Nexus 9500 series became a flagship product family — powerful, scalable, and reliable. Behind it is a chassis design that proves how Acorn helps industry leaders turn ambitious ideas into market-ready solutions that perform at scale.